In a normal year, at Rottaprint, you would hear many questions from our students getting excited about learning. But what does education look like in times of pandemic? Well, we found solutions and we adapted to the new context so that our students can learn further. In this uncertain environment, it is important that learning takes place, even if it cannot happen personally. We are glad that, unlike any time in the past, we have the ability to continue education even when schools are closed and when students cannot be physically present. We are committed to helping all of them have positive learning experiences, even remotely.

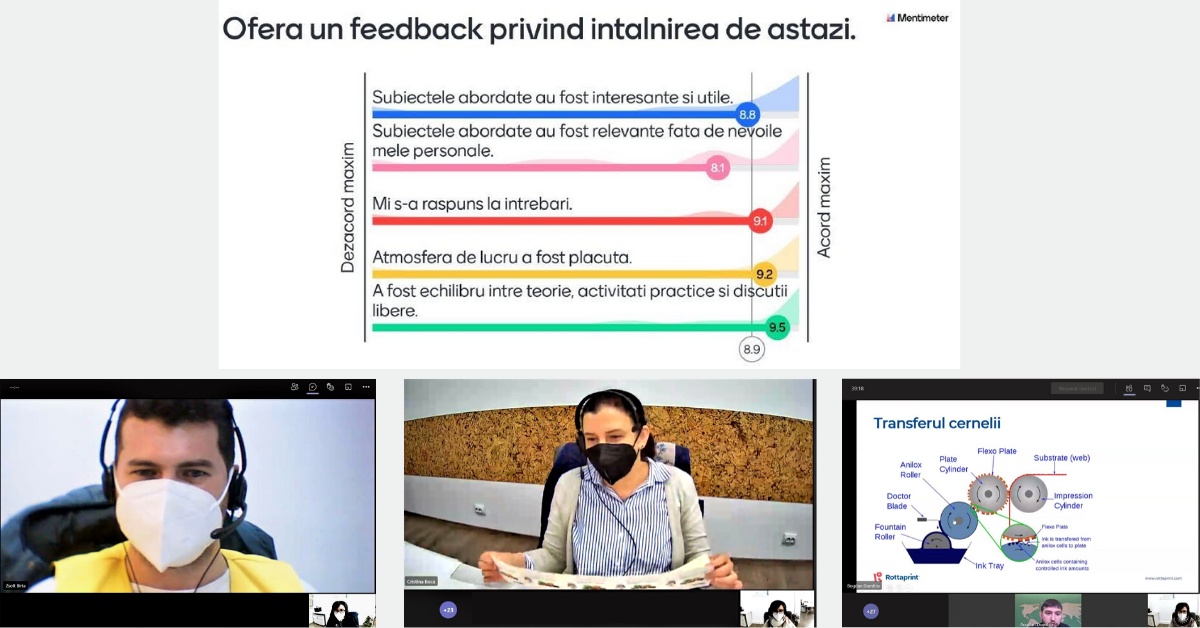

Of course, the internship program has been redirected towards the online environment. We have joined forces and created a strategy to adapt the learning process to the new situation. Once we had a clear vision of how it should look, we started working on it. Now students learn online through interactive presentations, free discussions, exercises, practical applications, games, projects, and virtual visits.

Our 90 students aged between 14 and 18, in the 9th, 10th and 11th grade from the Technical College of Communications “Augustin Maior” learn with us the secrets of typography. Printing Techniques and Media Production are the two fields they study.

What are they learning?

• The history and evolution of the polygamic field

• Everything they need to know about a printing company as a whole, how it is organized, what activities are carried out

• Examples of polygraphic products on a general level

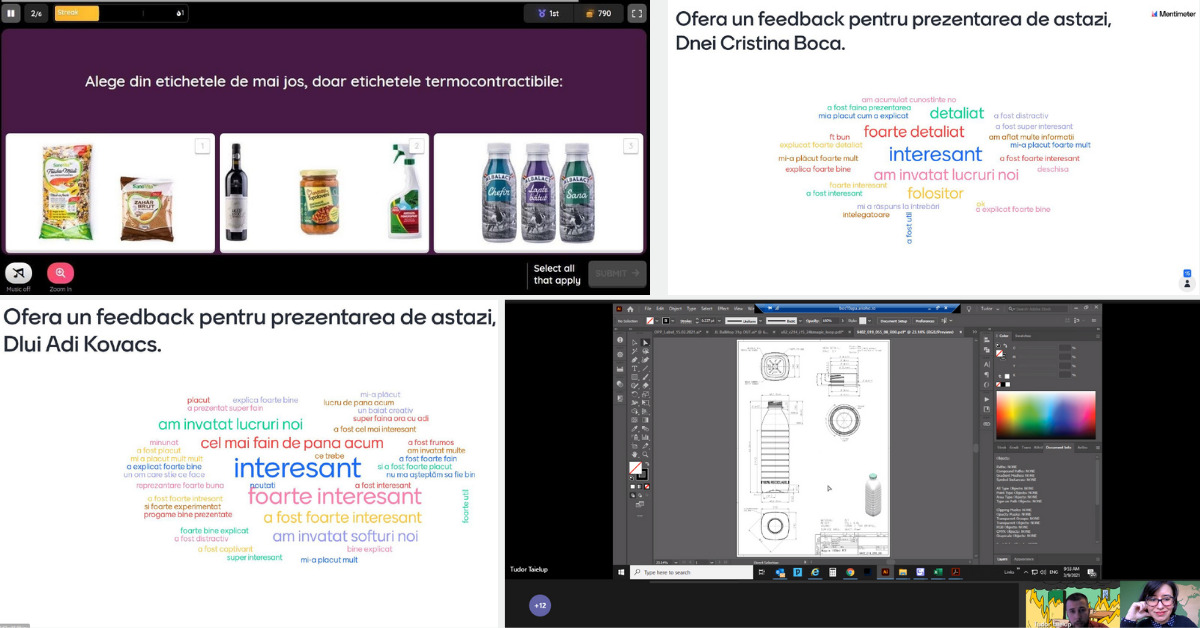

• Examples of printing products, specific to our industry: from self-adhesive labels, to lids, shrink sleeves, smart labels, etc., as well as how they are implemented for our clients

• Printing standards for our field

• Design, how the colors are used in printing, and how digital patterns are processed (digital text and image processing)

• The Prepress processes and procedures

• Printing using different printing technologies: flexography, offset, digital printing, screen printing

• Everything about materials, inks, adhesives, solvents – what are they, how many different types we use, and what is their role and impact on the finished product

• Other: How to place a production order, how the materials are purchased, the management of raw materials and test equipment & tools, how we deliver the finished product, etc.

Of course, the students are familiarized with the KAIZEN concept and how it is applied in our company. Students are encouraged to test KAIZEN tools (5S method, elimination of losses by solving problems, using visual management and suggestion system). And starting from simple and concrete examples, they can test out these principles of continuous improvement even at home or at school.

The class always starts by showing scheduled activities for the day. Then Rottaprint experts give the interactive lessons. Also, virtual visits take place within the departments, including in Production, so that students can see live what was presented to them. Last but not least, they have practical, individual and team-based activities. They work together and then, they are presenting the results of their activities. There are also debriefing sessions in which reflection, feedback, and questions are encouraged. The day ends up with a recapitulation and evaluations. Everything takes place through quizzes, interactive games and lessons, free discussion sessions and individual or group projects.

Most of our departments are involved in this process. So far, students have had the opportunity to learn from specialists in Human Resources, Marketing, Prepress, Production, Logistics and KAIZEN. As trainers, we have become more creative and found new ways to approach and support students during this period.

Is it easy? Certainly not. But it is an experience that also brings many opportunities. We get used to being more flexible and adapting to any new challenge. To use technology to our advantage. To be a team and work together even remotely. And we never stop learning.